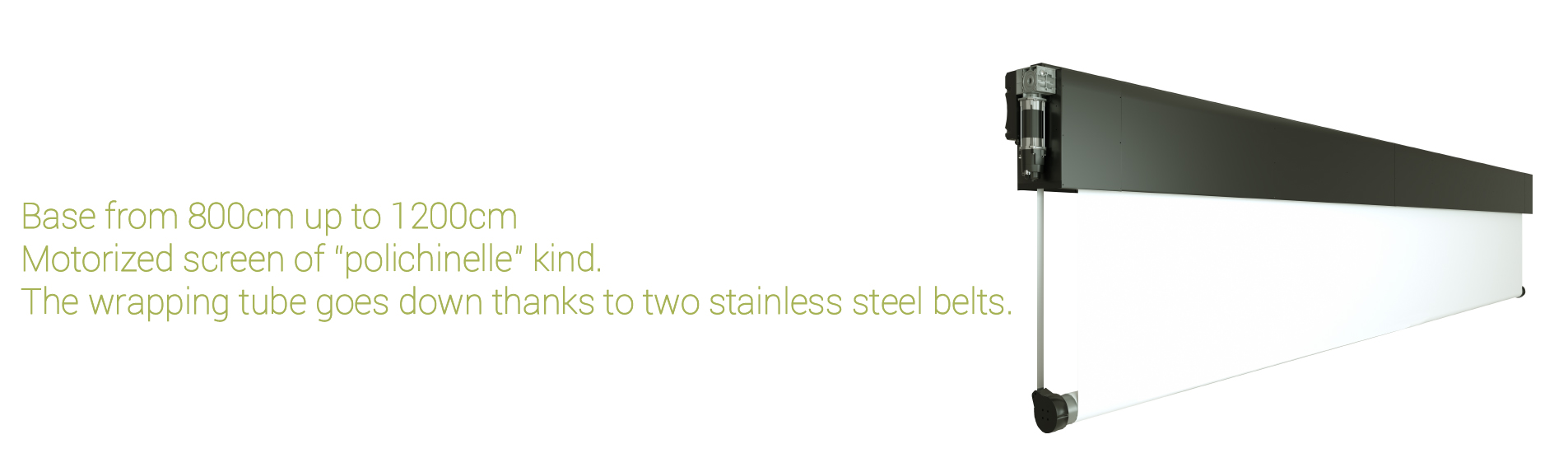

With “Polichinelle” system the wrapping tube goes down to the lower end stroke while unwrapping the projection fabric until it is completely open. The system uses two lateral cables to put the tube in motion. In our screen, the two cables are replaced by two stainless steel belts which, when wrapping up, avoid any possible overlapping or derailment. Compared to the previous versions,Maximilian also features two lateral stainless steel safety cables.

Two fall arrest systems at the extremities of the wrapping tube grant safety also in case of accidental cut of the fabric. The motion transmission mechanism inside the motor, provided with angular worm gearbox, is fail-safe in case of black-out and can be activated also by hand using the crank handle supplied. Each and every feature of the screen is designed to bear up to 20 times its own weight.

INSTALLATION

The aluminium supporting beam on the back of the screen holds four sliding plates which allow the installation of the screen with clamps, brackets and counter-brackets suitable for concrete, steel or wooden beams and available on request. The screen may weigh 285 kg in its biggest version. Due to its weight, chain winches for lifting installers up to the needed height are available for sale or rent. In the first case, they will also be used periodically for cleaning and maintenance.

MOTOR

The motor that provides the movement is controlled by an electronic unit which determines its speed and also the start and finish acceleration-deceleration. It has three or more pre-determined positions and can be remotely controlled, in turn, through an RS485 port.

SPEED RUN: 0,50 m/s